Overview

Precision Punch is a typical manufacturing facility located in CT. Faced with high energy costs they enlisted ECES to analyze the facility for Energy Conservation Measures (ECM). In our analysis we recommended retrofitting existing equipment with energy controls; saving energy with minimal capital outlay. Assuming a 3% inflation rate of energy and a company cost of capital of a modest 8% yields

Costs & Benefits

| Project Cost plus Taxes | $391,748 |

| Utility Incentives | $268,249 |

| Net Project Cost | $123,499 |

| Annual Energy Savings | $60,800 |

| Simple Payback | 2.0 years |

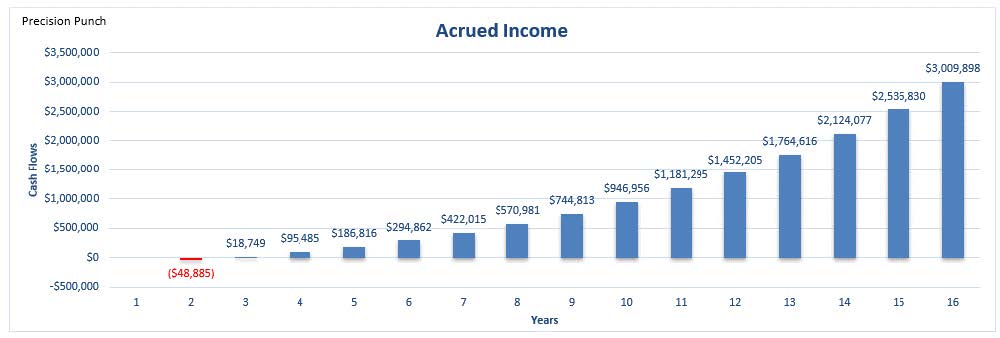

Long Term Savings